- PRODUCTS

- Refurbish

- Promotions

- New

- Liquid Handling

- Laboratory Glassware

- Weighing accessories

- Volumetric instruments

- Tubes

- Thermometers

- Test tubes

- SVS-Combi-Boxes

- Storage vessels

- Stopper

- Stirring

- Staining vessels

- Staining jars

- ST-Combi-Boxes

- Spare parts

- Sample vessels

- Sample preparation

- Round bottom flasks

- Reaction vessels

- Racks

- Petri dish

- Parafilm

- Object holders & coverglasses

- Miscellaneous

- Life Science

- Insulating vessels

- Glass plates

- Funnels

- Flasks

- Filtration & separation

- Experimenting

- Distillation & extraction

- Dishes

- Desiccators

- Cuvettes

- Cultivation vessels

- Condensers

- Component parts

- van Slyke apparatuses

- Valves

- Stoppers

- Stopcocks

- Spherical joint

- socket members

- Socket

- Pourers

- Needle valves

- HV-flat flanges

- High vacuum needle valve stopcock

- Gas collectors

- Function-stop

- Flow controller

- Connection tubes

- Cones

- ball members

- Bag-stopcock acc. to Schiff

- Angled stopcock acc. to Schiff

- Angled high vacuum stopcock

- 3-way-high-vacuum-stopcock

- 3-arms-stopcock

- 2-arms-stopcock acc. to Schiff

- 2-arms-stopcock

- 1-arm-stopcock

- Columns

- Colorimetry

- Chromatography

- Bottles

- Beakers

- Accessories

- with Cone

- Transition pieces

- SVS-screw-thread

- Support

- Stoppers

- Standard Alu-caps

- Silicone gaskets

- Short adapter

- Screw thread coupling

- Screw caps

- Reduction adapter

- Quick release clamps

- quick release clamp

- plastic

- PE-stoppers

- O-rings

- Labocap-Closures

- Internal center rings

- Internal center ring

- Hose connection

- Hollow stopper

- hexagonal plate

- Flat flange

- Expansion adapter

- Cork laboratory rings

- Conical-spherical adapter

- Clips for joints

- Caps

- Capillary pipettes

- Blood sedimentation apparatuses

- Blood diluting tubes

- Laboratory Equipment

- Water Purification System

- UV/VIS Spectrophotometers

- Spectrocopy

- Safety & purification

- Pharmaceuticals Testing

- Mixing & shaking

- Miscellaneous

- Microbiological

- Heating

- Glasswar Washing

- Gas-Generator

- FTIR

- Filtration & separation

- Environment

- Cooling & freezing

- Chromatography

- Atomic Absorption Spectrometer

- Consumables

- Writing tools

- Weighing accessories

- Volumetric instruments

- Vial and cap

- Tubings

- Test tubes

- Syringes

- Storage vessels

- Spherical ground joint sleeves

- Sleeves for joints

- Silicone stoppers

- Sieves

- Sample vessels

- Sample preparation

- Reaction vessels

- Racks

- Protective clothing

- Protective & cleaning papers

- Plastic vessels

- pH Buffer capsules

- Parafilm

- Miscellaneous

- Micro titration plates

- Means

- Labels

- Indicator paper

- HPLC/GC Column

- gloves

- Funnels

- Foil-welding apparatus

- Flasks

- First aid equipment

- Filtration & separation

- Electrodes

- Dropping pipettes

- Cuvettes

- Cultivation vessels

- Cryo articles

- Crucibles

- Conductivity standard

- Combustions boats

- Cleaning concentrates

- Cleaning brushes

- Chromatography

- Centrifuging

- Casseroles

- Bottles

- Bellow

- Beakers

- Baskets

- Autoclave bags / Waste disposal bags

- Aluminium foil

- Acessories

- Accessories

- COMPANY

- NEWS

- EXHIBITIONS

- TRAINING AT CHEMTECH

- CONTACT

- DISTRIBUTION PARTNERS

- DOWNLOADS

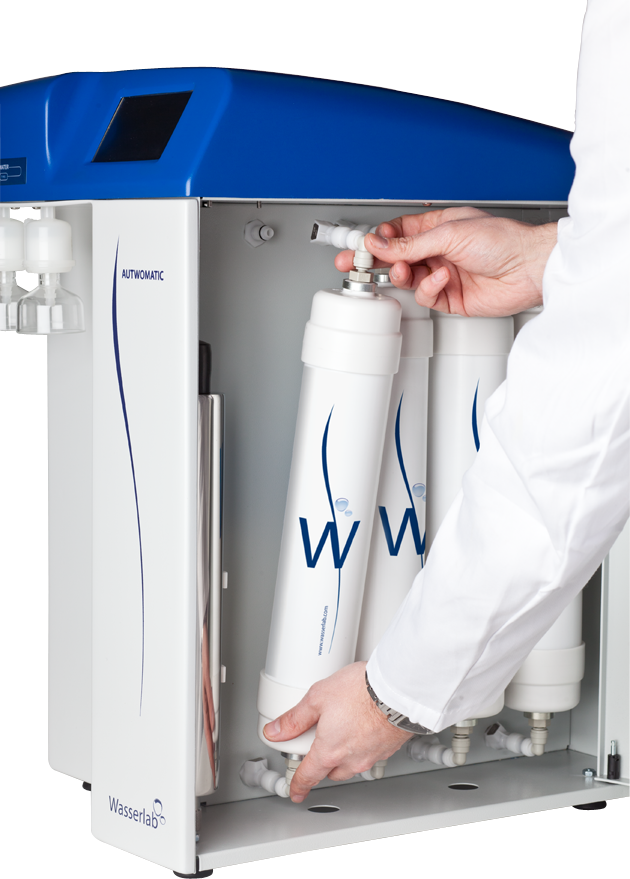

Autwomatic Plus 1+2

Desktop Water Purification System is able to produce three qualities of water:

– Type I Water (Ultrapure Water)

– Type II Water (Pure Water)

– Osmotized Water

The Autwomatic Plus 1+2 produces and dispenses Type I and Type II water from tap water, with the following characteristics:

Categories: Laboratory Equipment, Water Purification System

Description

Description

| Versions | Code | Type II Water | Type I water | |||||||

| Production Rate | Purification Module | Storage Tank | Final Filter 0.22 μm | Production Rate | Ultrapurification Module | Foto-oxidation Lamp | Ultrafiltration Cartridge | Final Filter 0.22 μm | ||

| Autwomatic 1+2 – 3 l/h GR |

QA03DPGR | 3 l/h | X | 10,30,50 Liters | X | 2 l/min | X | X | – | X |

| Autwomatic 1+2 – 5 l/h GR |

QA05DPGR | 5 l/h | X | 30 or 50 Liters | X | 2 l/min | X | X | – | X |

| Autwomatic 1+2 – 10 l/h GR |

QA10DPGR | 10 l/h | X | 30 or 50 Liters | X | 2 l/min | X | X | – | X |

| Autwomatic 1+2 – 3 l/h GRUF |

QA03DPGF | 3 l/h | X | 10,30,50 Liters | X | 2 l/min | X | X | X | X |

| Autwomatic 1+2 – 5 l/h GRUF |

QA05DPGF | 5 l/h | X | 30 or 50 Liters | X | 2 l/min | X | X | X | X |

| Autwomatic 1+2 – 10 l/h GRUF |

QA10DPGF | 10 l/h | X | 30 or 50 Liters | X | 2 l/min | X | X | X | X |

Type II Water

| Production: | 3 – 5 – 10 l/h |

| Conductivity | < 1 µS/cm |

| TOC | < 30 ppb |

| Bacterial content | < 0.01 ufc/ml |

Type I Water

| Flow rate: | 2 l/min |

| Conductivity | < 0.055 µS/cm |

| Resistivity | 18.2 MΩ·cm |

| TOC | < 3 ppb |

| Bacterial content | < 0.01 ufc/ml |

| Endotoxins *

Free of Pyrogens and nucleases |

< 0,001 (IU/ml) |

*GRUF version

In the purification process, the tap water is treated in different stages of purification to obtain Type II and Type I Water, in two separate dispensing points

Process for obtaining

Type II water:

1.-Pretreatment (External to equipment)

2.- Reverse Osmosis

3.- Osmotized water reservoir Water produced after reverse osmosis is stored in a pressurized and hermetic tank (10/30/50 liters). This way, water is protected against contamination and air contact. From the tank, the Osmotized water can be used for feeding washing machines or any other device that requires this quality of water.

4.- Deionization step

5.- Foto-oxidation Lamp with germicidal effect.

6.- Final Filter – 0,22 µm

In order to achieve even more stringent microbiological requirements a final filter is placed in the dispensing point, thus retaining any microorganisms present in the final water.

Process for obtaining Type I Water:

1.- Ultrapurification deionization module.

2.- Photooxidation lamp for TOC reduction

3.- Refining Module for Ultrapure Water

4.- Ultrafiltration Module (GRUF Version)

5.-Final Filter – 0,22 µm

Touch Screen

The equipment has a color screen Touch 4.3 “, which works as the user interface and displays the control parameters of the water purification process and the corresponding messages. Monitoring

The equipment dispenses Type II and Type I Water independently.

Reading device parameters

• Conductivity of the feeding water.

• Conductivity of the permeate reverse osmosis’ permeate.

• % perfomance of the reverse osmosis module

• Conductivity of the Type II water.

• Resistivity of the Type I water.

• Temperature of the water .

Total control of parameters:

• Hours of installation for each item.

• Working hours of each item.

• Total liters produced.

• Pumps operating hours.

Customization of Equipment

The equipment allows three different types of dispensing:

– Directly by touch. Direct Touch and continuous dispensing.

– By volumes delivered. Programmed dispensing volume in milliliters.

– On time selection. Dispensation of time programmed in seconds.

Allows fixing the alarm conductivity, according to user’s needs work.

Security

The system has a custom password for the user, to access certain features Automatisms Systems available:

• Stop by water cut.

• Cleaning osmosis membrane drag combined with conditioning with RO water to extend its life.

• Programmable Type I Water Recirculation. Recirculates automatically the water contained in the circuit, ensuring the highest quality of dispensed water .

• Inability to dispense water with less than a preset resistivity.

Self Test and Preventive maintenance

The Autwomatic 1 + 2 Software is pre-set to perform a scheduled self-check system operation, exercising a constant and effective control of the equipment components and values for monitoring the quality of water produced.

The equipment alerts of the change of consumables

And for malfunction of the equipment, such as

• Cut of inlet water.

• Malfunction of the measuring probes.

Maintenance, sanitizacion and Calibration

The replacement of consumables is very fast, because the cartridges have a quick connect system with anti -drip system.

The system allows the sanitization, using a semi-automatic system.

The software allows to set up and calibrate the conductivity meter by using a certified standard with traceability to the national standards from the German Deutscher Kalibrierdienst (DKD).

Reviews (0)

Be the first to review “Autwomatic Plus 1+2” Cancel reply

Reviews

There are no reviews yet.